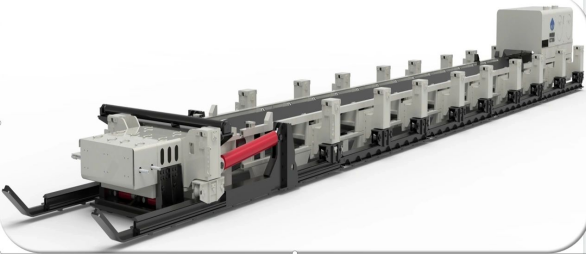

Self-moving tail for belt conveyor

Brief introduction

Self-moving tail for belt conveyor is an auxiliary transportation equipment used for underground excavation in coal mines. It works in conjunction with the excavation belt transfer machine to ensure the efficient transfer of excavated materials. This machine is equipped with its own electric and hydraulic system, which enables it to move through the lifting, pushing, and deflection of the tail without requiring external power.

The self-moving tail overlaps with the belt loader through the lap trolley with a long lapping stroke that effectively reduces the number of tail movements and labor intensity of workers, ensuring efficient and rapid tunnelling, safe and low-cost operation. Moreover, the self-moving machine's tail has a receiving hopper that can be used with the existing crawler-type reloading crusher.

The machine's step-moving mechanism enables step-type rapid self-movement, thereby achieving the mechanization and automation of the belt conveyor tail. Our company successfully developed the first intelligent long-distance stepping self-moving tail in China, which was successfully applied in the demonstration tunnelling working face of the National Energy Shendong Coal Group.

The application of this self-moving tail has revolutionized the tail-pulling process, shortening the auxiliary operation time by more than 50% and reducing the labor intensity of workers by more than 60%, thereby improving the working environment and safety and providing a solid guarantee for the high-yield and efficient mining of intelligent tunnelling face.

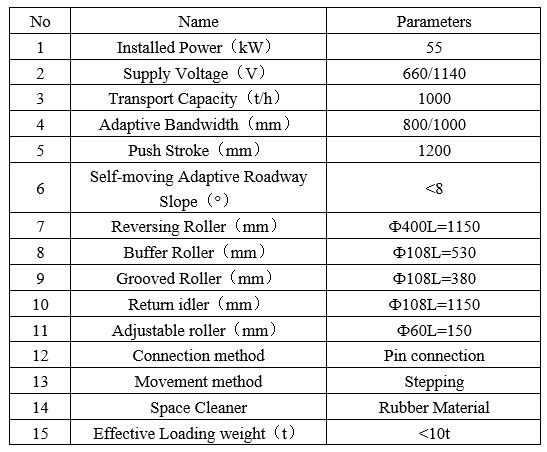

Technical parameters

Self-moving tail for belt conveyor parameters

Scope of Application

The telescopic belt conveyor extension device is designed for use in coal mine roadway excavation operations. It ensures the mechanized extension of the tail of the conveyor in the roadway and enables long-distance overlap with the belt loader, allowing for continuous operation of the conveying system after excavation and effectively improving the efficiency of roadway excavation.

This device is suitable for use under the following conditions:

Coal mines containing explosive gas mixtures such as gas

Operating environment temperatures between -5℃ and +40℃

Relative humidity of surrounding air not exceeding 95% at +25°C

Altitudes not exceeding 1000m

Environments with no gas or vapor that could damage insulation

No long-term continuous dripping

Flat bottom plates that do not become muddy when exposed to water.

Key features

The self-moving tail is equipped with an electronic control system that enables manual control of the enttext-align:justify;ire machine as well as wireless remote control. Remote control can also be achieved through the remote centralized control centre of the excavation working face, enabling real-time detection, display, and data storage of equipment operating parameters.

The travel, position, and other sensors equipped in the equipment enable one-key self-moving of the tail of the self-moving machine. The video monitoring system can transmit images of the equipment and environment to the underground and ground centralized control centre for remote monitoring.

Hot News

Hot News2024-02-18

2024-02-19

2024-02-06